GeForce Garage: Antec 900 Series, Video 5 - How To Use CNC To Make Custom Parts

OK, so we didn’t get jetpacks. That sucks. On the other hand, it’s now commonplace to see affordable 3D printers, CNC routers, and even laser cutters in the garages of hobbyists, craftspeople, and modders. These machines make experimentation inexpensive and painless, and give you the kind of results that would otherwise have cost you and arm and a leg at a machine shop or fabrication facility—and that’s assuming they’d even take one-off, non-commercial orders in the first place.

These days, you can print your own copy of a gadget you find on the web (like, say, a Pip-Boy 3000) on a 3D printer that costs less than a grand (with some smaller models going for as little as $200). If you’ve got a couple grand lying around you could also bag yourself a personal laser cutter or engraving machine that allows you to work on a wider range of materials like leather, wood, and fabric.

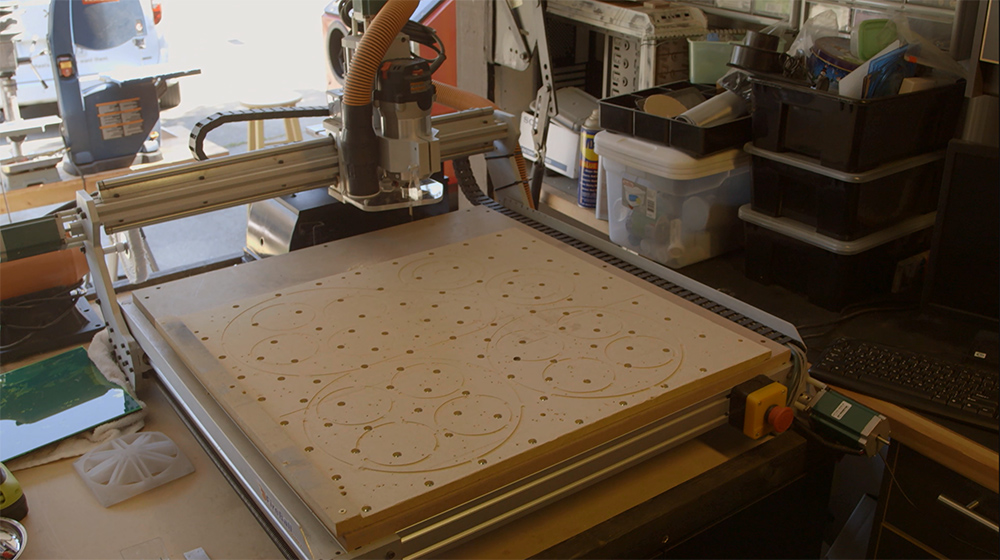

But the most practical and versatile investment for many modders is likely to be a personal CNC machine. Depending on the machine specs and the type of drill bit used, CNC routers can carve components, designs, and mods out of plastic, metal, wood, and even transparent materials like acrylic at the touch of a button.

CNC stands for computer numerical control, and CNC routers work in a similar way as 3D printers: you create a design in a 3D modeling program, and the resulting file is converted by special software into a series of instructions that tell the machine where to cut, and in what direction, for how long, and how deep. And, of course, once you’re satisfied with a mod that you’ve machined, you can use the same file to produce the exact same object over and over again.

In this video, we hiked it over to the home of Thomas “Whitelightlaser” Harrell of mainframecustom.com, where he walks us through the process of developing a machinable 3D file from a 2D design to create a pair of luscious translucent chassis side badges backlit with LEDs. If you’ve got your own CNC router or have access to one and you want to get right down to business, you can download Harrell’s sweet design here and use the accompanying PDF to the video to walk you through the process.

Thomas is a professional modder, and the CNC router he’s using with that roomy two-foot square bed costs about TK. But just like 3D printers, you’ll almost certainly be able to find find a CNC router intended for home use that strikes a good balance between capability and affordability, from the $999 Shapeoko 3 to the $3,500 five-axis Pocket NC. (Your correspondent is extremely happy with his Nomad 883 Pro CNC Mill, which is fully enclosed for indoor use and starts at $2,600.)

No, they’re still not jetpacks. But hey, CNC routers don’t spew tons of carbon dioxide into the atmosphere, and they won’t kill you after a bad landing.

For other skill guides involving the Antec Nine Hundred:

- Episode 1: How to Cut a Case Window

- Episode 2: How to Install a Motherboard Skirt

- Episode 3: How to Prep and Paint Your Case

- Episode 4: How to Hand Lace Your Cables

- Episode 6: How To Detail Your Rig With Airbrushing

SPECIAL THANKS TO: |

||